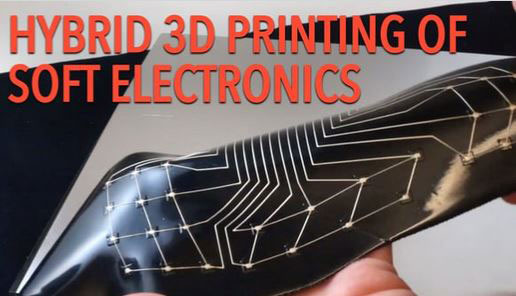

Our smart wearables are going to become even more sophisticated in the future with flexible electronic components. Researchers from Harvard’s Wyss Institute and Harvard SEAS have already developed a new 3D printing platform to integrate soft and hard electronic elements into stretchable sensors that move with the body.

More items like this: here

As they explain:

This is achieved by first printing a stretchable conductive ink. As the printed ink is stretched, its electrical resistivity increases. Next, surface mounted electrical components are digitally pick-and-placed in precise locations.

The printed wearable sensor is mounted on a stretchable textile fabric. Such approach can be used to develop more sophisticated smart wearables with flexible properties.

[HT]

*Disclaimer*Our articles may contain affiliate links. As an Amazon Associate we earn from qualifying purchases. Please read our disclaimer on how we fund this site.